At RRGR, our meticulously systematized process ensures we deliver the best. Before each piece undergoes hallmarking, we conduct a thorough analysis in compliance with the Bureau of Indian Standards (BIS) guidelines for the manufacture of gold jewelry, specifically IS-1417 and IS-2112.

Additionally, we work closely with our clients to gather comprehensive details about their items. This collaborative effort allows us to segregate the pieces into distinct lots, ensuring transparency and consistency throughout the process. It also aids in obtaining the most representative samples, particularly when dealing with intricate, multi-component traditional Indian jewelry, which requires precise handling due to its complex design and multiple soldered components.

At RRGR, our selection process is as meticulous as the final product that leaves our facility, with customer satisfaction being our ultimate goal. We carefully choose pieces from each lot, ensuring that the selection is based on the design and manufacturing criteria. The selected gold/silver is then scrapped from the appropriate locations for accurate sampling.

The scrapped material is weighed on a precision balance to ensure accuracy and is subjected to fire assaying for gold or gravimetric and Potentiometric Titration methods for silver, following the applicable Indian Standards: IS-1418 for gold and IS-2113 for silver. Once the fineness of the samples meets the declared purity, the representative jewelry or artefact lots undergo hallmarking.

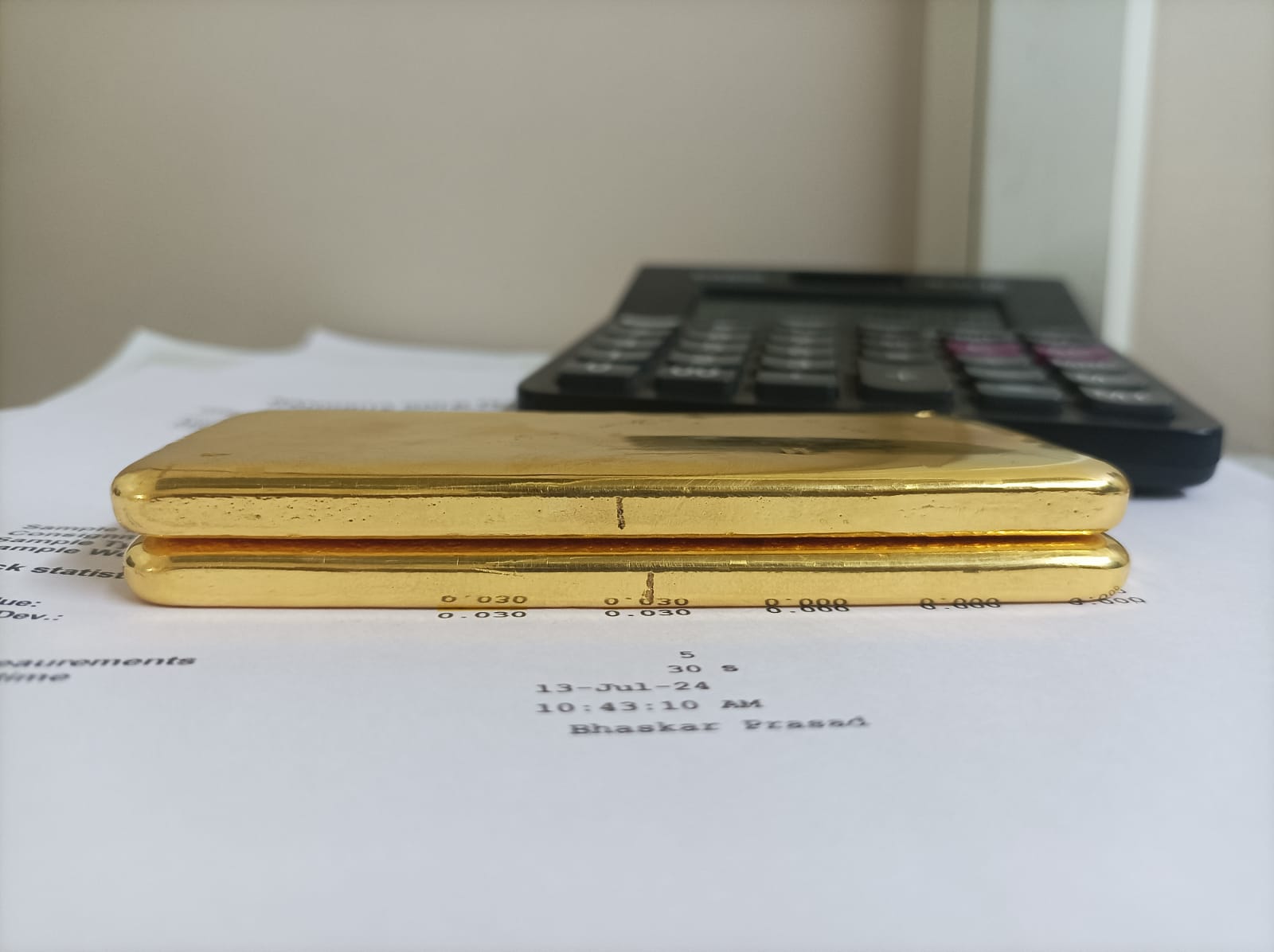

Each BIS hallmarked bar carries a unique serial number and stamp, distinguishing it from standard production bars. This added layer of quality control has helped us establish ourselves as a trendsetter in the industry, consistently driving positive change and growth in the trade.

At RRGR, we believe that inscribing an official mark enhances confidence in the products we offer. That's why we use a CNC Laser Marking machine to hallmark every piece of gold jewelry. This advanced technology authenticates the purity of the gold through a non-impact method, ensuring no damage, such as sinking or bruising, occurs to the items.